Cutting Thin Aluminum on a CNC

Cutting thin aluminum on a CNC router is fairly easy once you know the tricks. Here is what you do:

-

Set the feed rate to about 500 mm/minute (20 inches/minute).

-

Set the spindle speed to about 10,000 rpm.

-

Use climbing-cuts (opposite direction than when cutting wood).

-

Use an O-Flute bit specifically for aluminum.

The problem with cutting aluminum is that the chips get really soft and sticky in that brief moment when they are cut free. If you try to use a standard router bit at full speed, you will simply clog the flutes of the bit. You will not last more than a few seconds! So, you have to slow down the spindle speed just a little. And, most importantly, use the right bit.

I like to use either an 1/8 inch or 3/16 inch diameter bit; I do a lot of detailed work. I get that in downcut, and the special bit type is called an O-Flute. An O-Flute has a single, smooth, continuous, and slightly larger flute radius. The soft sticky aluminum chips slide right off, no coolant required.

- Amana Tool 51 series: 51772, 51773, 51774

- LMT-Onsrud 64 series: 64-012, 64-018, 64-025

Since I cut mostly thin sheet, and there is not a good way to hold the whole sheet down to the table, there is a trick here too: I use a downcut router bit. When cutting, the bit pushes the material down against the table. This keeps the thin material down in place and avoids chatter, tearing, and all kinds of problems.

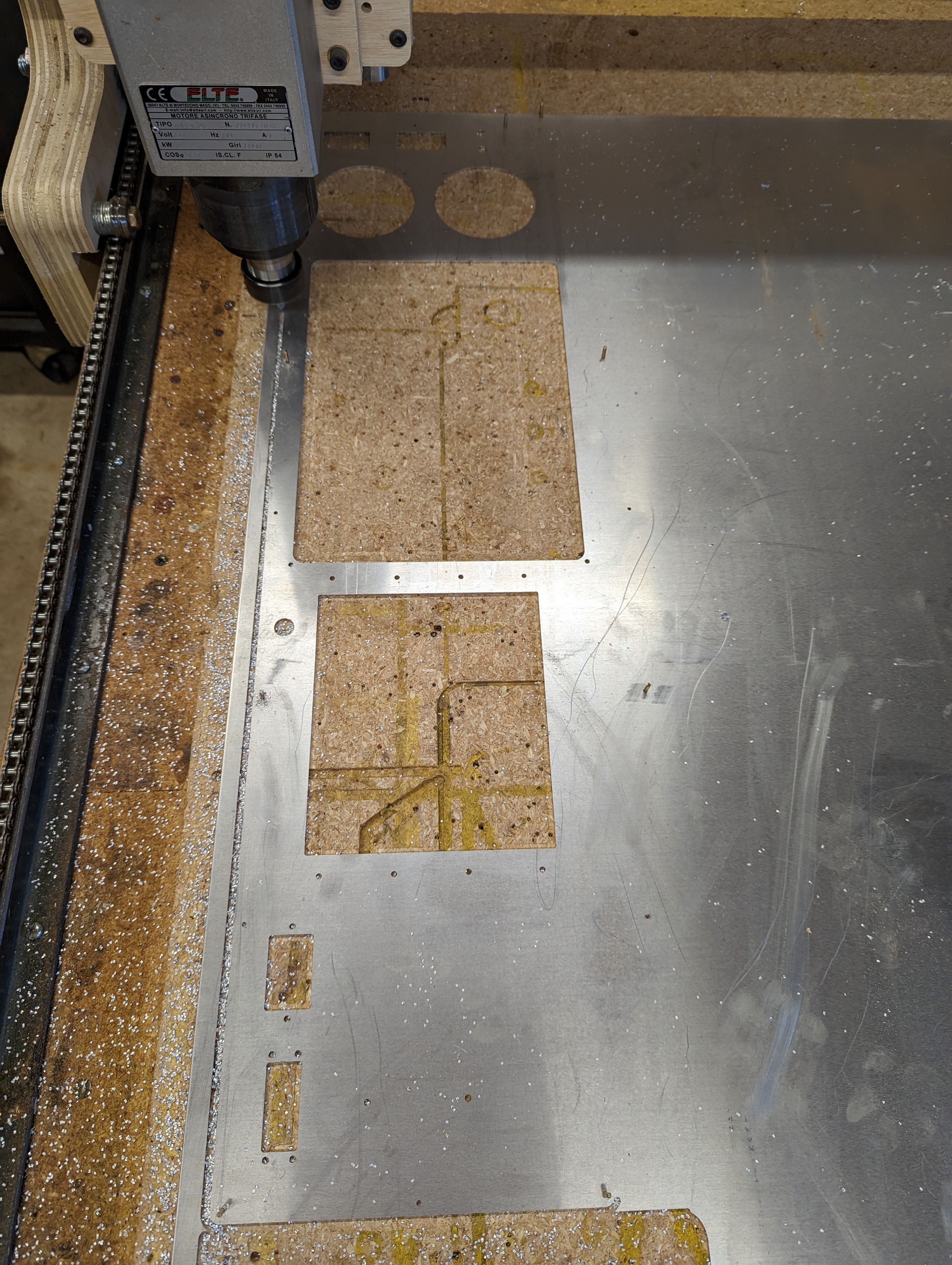

With the downcut bit holding the material down, I only have to worry about side to side containment. I typically drill with a 3/32 inch bit through the aluminum sheet and down into the CNC spoilboard about a 1/2 inch. And in that hole I push a 3/32 inch pin. The pins are basically TIG welding filler rod cut in 3/4 inch lengths.

Finally, I have found that when cutting wood a traditional-cut (left to right) leaves a better finish, and when cutting aluminum a climbing-cut (right to left) leaves a better finish. A traditional-cut for wood is necessary since that direction cuts the wood fibers more neatly. A climbing-cut for aluminum avoids gouging, grabbing, and chatter. If I really want a nice finish, I make a second finishing pass taking off 0.2 mm (0.008 inch)... or sandpaper works too.

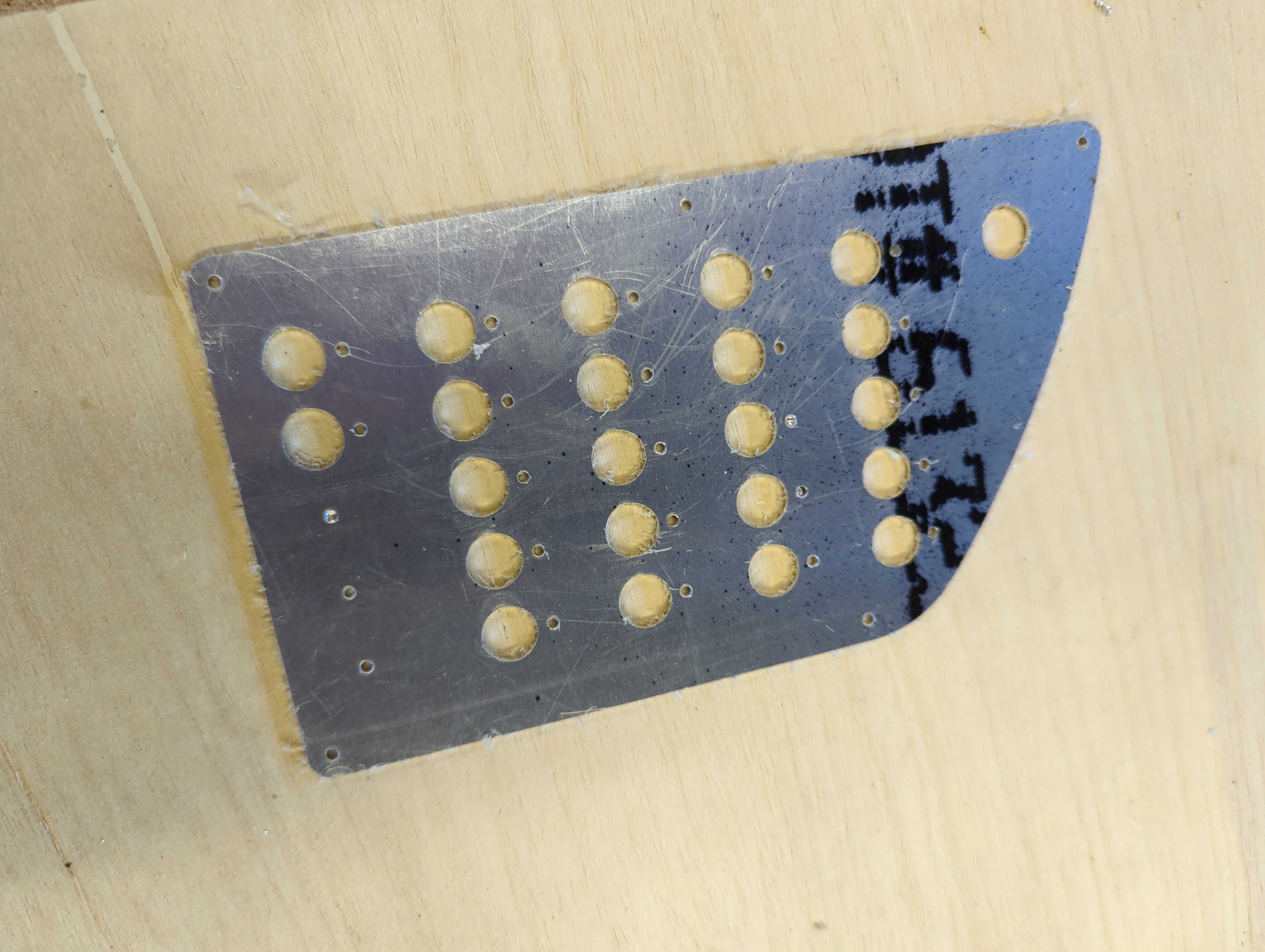

Speaking of which 200 grit sandpaper is a nice way to sand down the surface, remove burrs, hide bigger scratches, and give it a jeweling / engine turning finish. 100 grit just scratches too deeply, and 400 grit gives aluminum an opaque / buff finish.

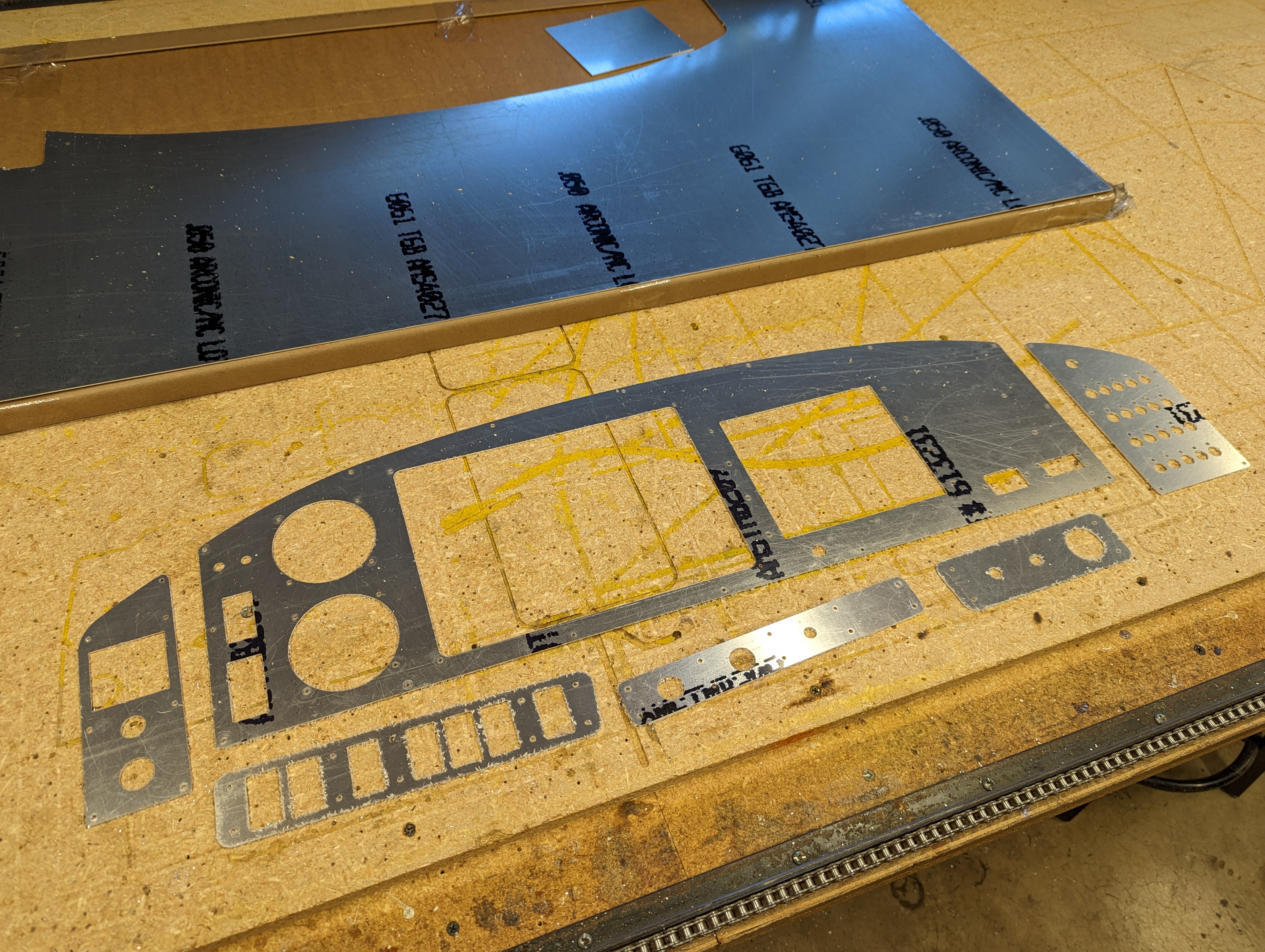

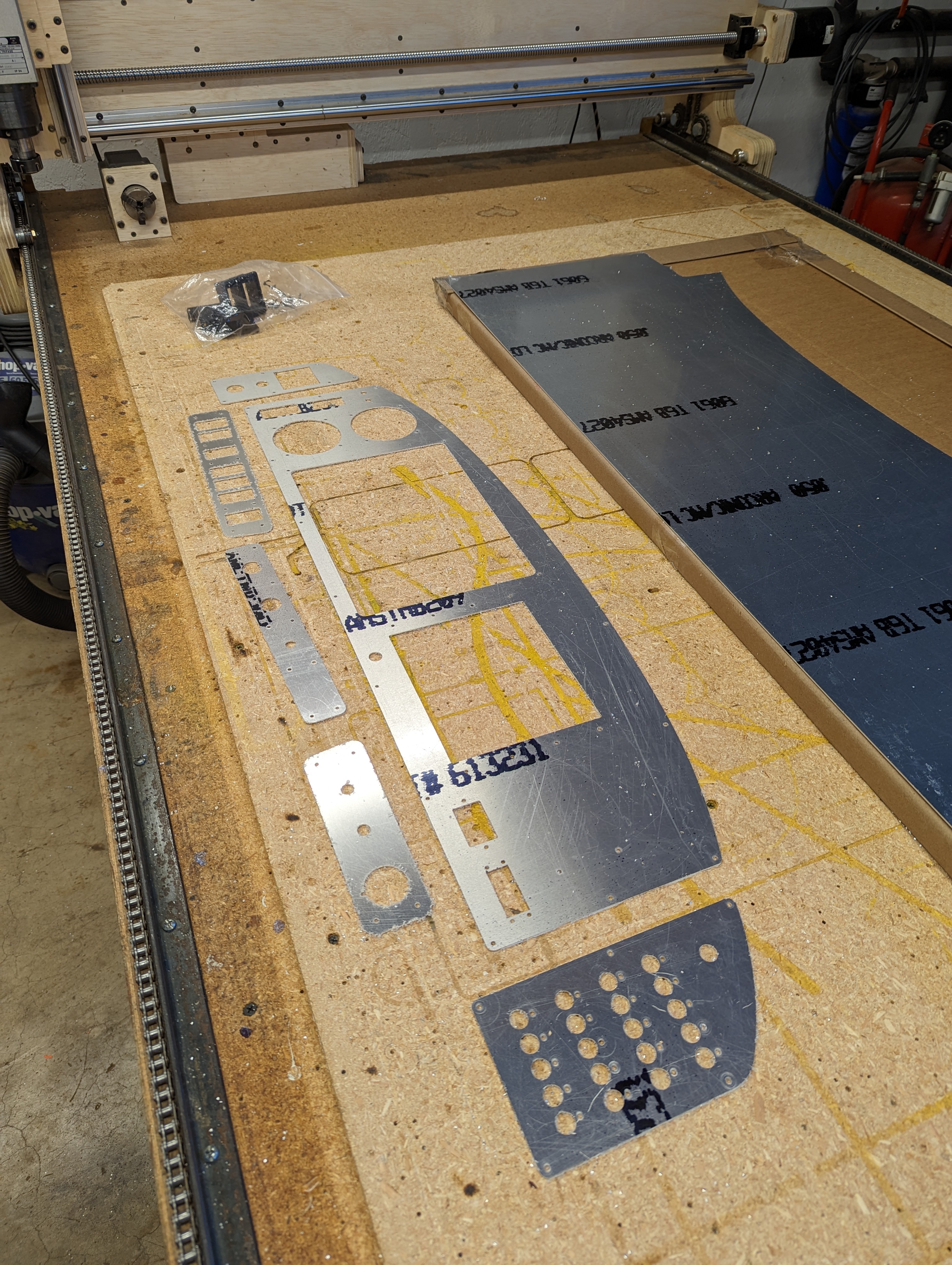

Aircraft Instrument Panels

Below is an example of cutting thin aluminum: an aircraft instrument panel. I have cut several instrument panels. These have to be very accurate, and at times when a blank is brought to me the owner they paid a lot of money for it. No pressure Robert, no pressure!

Instrument panels are typically 0.050 or 0.062 inch 6061-T6 aluminum. This is a bit thicker than the 0.020 to 0.040 aircraft parts and skins. So I just cut a touch slower. And below you can see the holding pins:

Aluminum sheet at times comes with a plastic coating. I just leave that on (this is why these parts looks all scratched up, but it is just the plastic):

Keep building!